Overview

BACKGROUND

Executive Summary of Clinker Free Slag Cement Technology (SlagCem)

What is it

A patent pending clinker and gypsum free green cement technology containing more than 85% Ground Granulated Blast Furnace Slag (GGBFS) activated by proprietary chemicals, complies to ASTM C 1157 (Specification for Hydraulic Cements).

How it works

The binding phase of SlagCem is formed at room temperature by reactions between various metal oxides and phosphosilicates under alkaline conditions yielding stronger Si-OP-Al-O bonds.

Why use it

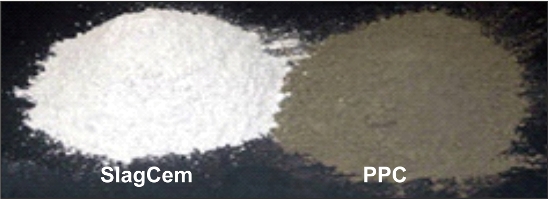

Increased durability, improved aesthetics (Off white in colour), increased acid, sulphate and chloride resistance comparing to PSC.

Why this technology

Quantum leap reduction in carbon foot print, maximized utilization of industrial by product, manufactured by simple powder blending operation and hence cement manufacturing plant at reduced investment and infrastructure.

How used

In the same way as normal Portland cement and hence easy adoption.

Why Eco Materials India LLP

Independent research lab and not bound by any factor to transfer technology, We do a continuous research to be at the fore front and our new inventions are constantly updated to our clients, With inhouse skills we provide quick, quality and responsive service.

INVENTION BACKGROUND

Depleting quality raw materials, increasing energy cost and pressure on emission reduction leads to an urgent need to develop for alternate and sustainable binder technologies across the globe which are going to be the driving factor of the future business. On the other hand rapid industrialization generates more and more byproducts which needs to be effectively utilized.

Generally Portland Slag Cement are made with GGBFS loading of upto 55% in different parts of world. Future significant reductions in concrete's carbon foot print can come from increased loading of GGBFS alone since it has a legacy of 100 years with consistent increase in its loading. However, People are very sceptical to increase the loading of GGBFS beyond 55% in the conventional Portland Slag Cement because of slow strength gain and increased set times.

While at Eco Materials India LLP, we were successful in rolling out different binders based on acid-base chemistry, focussed its R&D efforts in the past 5 years to develop a high volume GGBFS based binder "SlagCem" using similar technique.

EXCLUSIVELY FROM ECO MATERIALS INDIA LLP

We research, invent and offer game changing technologies in material science enabling our clients to achieve competitive edge, improved market position, new market reach supported by our world class research lab and product development team.

We are specialized in developing technologies in the area of zero cement alternative binders, green cements, innovative coatings, artificial aggregates, advanced building materials, effective utilization of industrial by products and hazardous waste stabilization.

Eco Materials India LLP team of renowned scientists and engineers embraces decades of legacy of material science research and innovation dedicated to the advancement of quality and performance predominantly in the challenging arenas of building material industry. Our technical efforts are headed by Dr. N. Ramkumar, a doctorate in material science from University of Illinois, Chicago, USA has more than 10 years of research experience, worked with US national level laboratory and worked for global clients including fortune 500 company in USA, Oil & Gas firm in Canada, etc. and involved in developing a novel “Alloyed & Flexible Ceramic Anticorrosive Coating” for a USA based company.

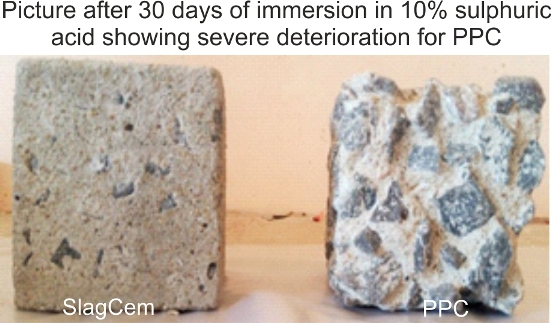

INCREASED ACID RESISTANCE

SlagCem resists corrosive effects of acids because of the absence of calcium hydroxide and calcium - silicate - hydrate which are the two minerals that causes Portland cement to fail when exposed to corrosive acids.

KEY PROPERTIES

SlagCem uses 85-90% Ground granulated blast furnace slag (GGBFS) in accordance to BS 6699 / BS EN 15167 with adequate fineness and having a glass content of 90% minimum. It does not contain any clinker or gypsum. It is activated by a cocktail of proprietary chemicals, activator dosage and percentage of GGBFS loading depends on the chemical characteristics and fineness of GGBFS.

BINDER PROPERTIES AT A GLANCE

With our binder technology, one can now have concrete that is superior in almost every way to the concrete that has been traditionally used. Concrete made with SlagCem will have the following properties.

- Stronger

- Increased durability

- More impermeable to water

- Higher resistance to sulphate and chloride attack

- Substantially increased immunity to acid attacks

- Reduced heat of hydration

- Improved solar reflectivity

- More resistance to fire

- Increased resistance to alkali silica reactivity

- Decreased environmental impact (Low CO2Cement)

NO FREE CALCIUM HYDROXIDE AND MORE DURABLE

Although Portland cement has been used for many years, it is not without limitations. It is susceptible to attack by chemicals such as sulphates and chlorides and has undesirable reaction with certain aggregates containing Silica because of the presence of certain mineral phases like tri-calcium aluminate and free calcium hydroxide.

The quest for a more durable and sustainable cement drove our efforts in R&D that led us to invention of SlagCem. It does not contain free calcium hydroxide and its related short comings. At the same time the inherent chemistry of our binder takes care of the loss of alkalinity due to the absence of free calcium hydroxide responsible for the corrosion protection of rebars.

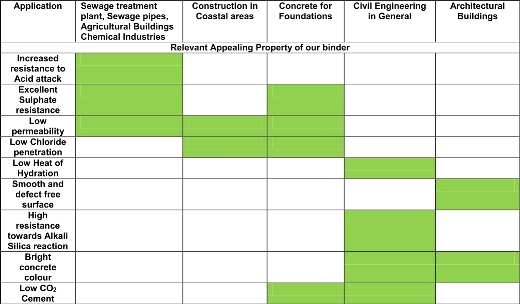

Property related Application Matrix

The remarkable properties because of increased usage of GBFS in the cement formulation have been published internationally in the past years. SlagCem’s unique and improved properties gives broad access to the market of precast and ready mix concrete especially in the high quality, highly corrosive and premium segment.

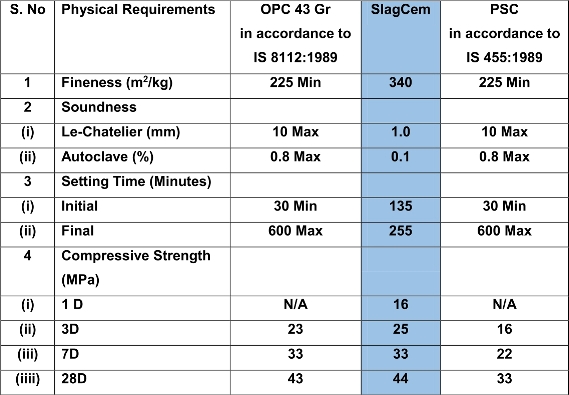

Testing And Validation

Sustainability

Concrete is one of the most versatile building material available in the world today and its popularity can be seen by the fact that it is the second most widely consumed resource in the world with water being the only resource to exceed it.

Whilst being the world's most used building material, modern concrete is not recognised as one of the most sustainable. Portland cement (OPC) generates 913kg of CO2 for each tonne of finished product. It accounts for around 5-8% of total CO2 emissions in the form of greenhouse gases, making it the third highest man-made producer of CO2 after transport and energy generation. SlagCem activates more than 85% GGBFS producing an ultra-low carbon alternative to concrete mix designs that traditionally use Portland cement - “A quantum leap reduction in carbon foot print due to materials innovation”.

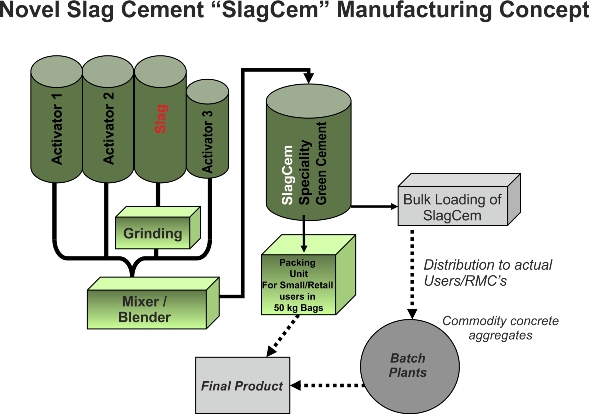

Manufacturing Process: Doesn't involve the energy consuming Pyro-process and hence it is more energy efficient, produced through specialized blending operation with or without Classification / Grinding, depending upon the GGBFS quality and consistency.

Low Energy Plant: Our Green Cement plant consumes up to 90% lesser energy than that of a conventional OPC plant of equivalent capacity, which depends on GGBFS quality and consistency.

Emission Free Plant: Due to the elimination of Pyro-process, CO2 SOx and NOx emission with respect to process is zero.

Green Cement: Due to elimination of major systems like coal handling / crushing, gypsum handling, clinker grinding, etc. and its related equipment, our carbon foot print with respect to energy usage is many folds lesser than that of a conventional OPC plant of equivalent capacity - Preserves virgin materials and conserves water.